To consolidate its technology leadership, it is imperative for weba to continuously invest in new machines and methods. Particularly important is ensuring product quality during production. For this reason, the company has expanded its quality laboratory and is now able to perform metallographic analyses and mechanical material testing, in addition to the proven tactile and digital measuring systems.

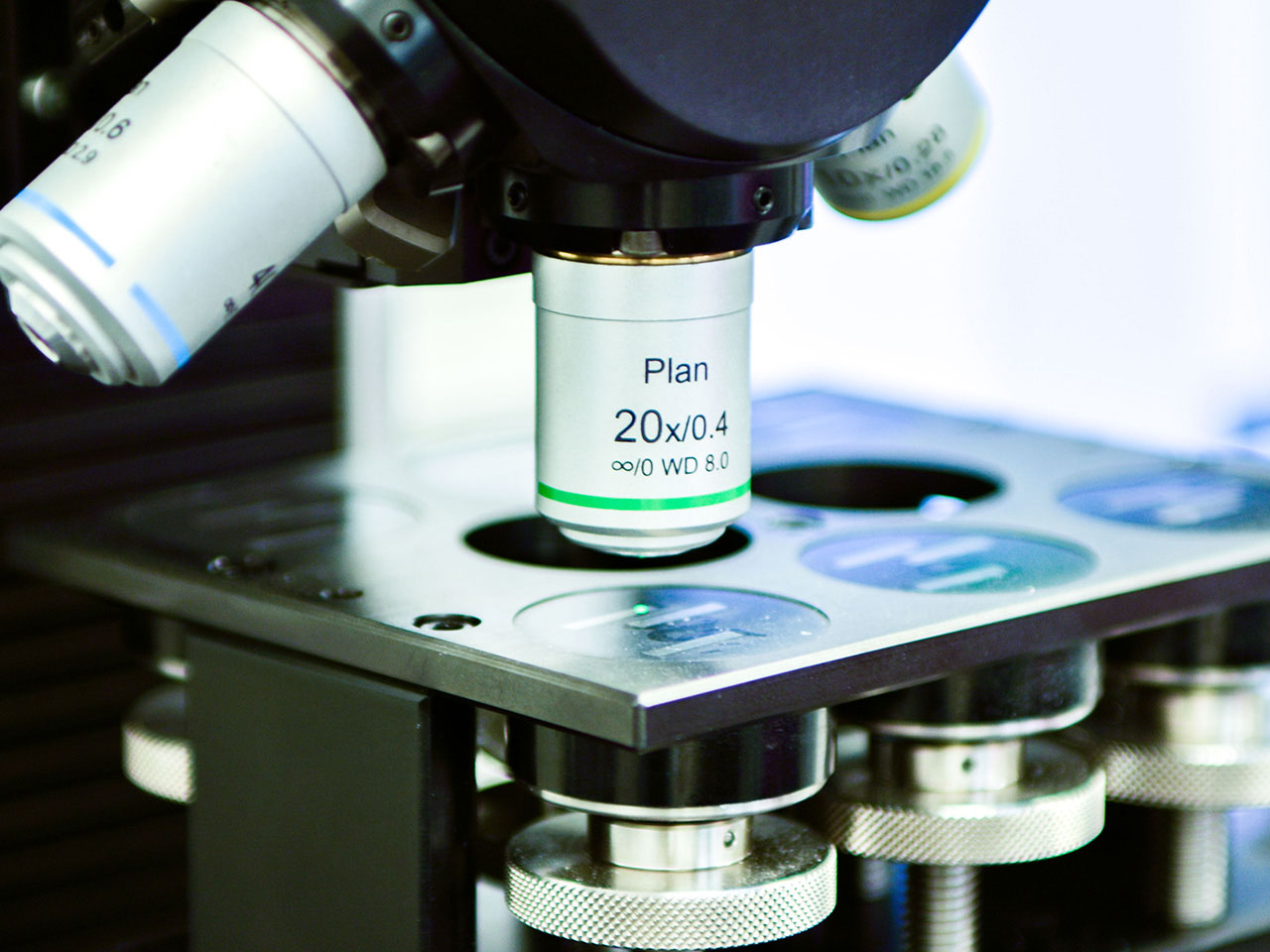

The extensive equipment of the quality assurance laboratory is impressive. For the preparation of material samples for hardness testing and microscopic examinations, a wet cutting machine and a hot embedding press, as well as a grinding and polishing machine, were acquired. Additionally, a micro hardness tester, a microscope camera, a bending and tensile testing machine, an HRC hardness testing device, and an additional 3D scanner were integrated into the measuring and testing technology. These state-of-the-art devices enable optimal measurement and testing controls.

A crucial motivation for investing in laboratory technology is the improvement of quality requirements in daily production and the verification of the self-developed process monitoring at the automated hot forming plant. Hannes Feuerhuber, Managing Director of weba, emphasizes: 'With meaningful test results regarding material and component properties, we can implement further process optimizations in hot forming with great confidence.'

The goal of weba is to provide its customers with the highest quality products and to take another step towards technology leadership with the investments in the modern quality laboratory. Continuous development and modernization enable the company to meet the rising demands of the automotive industry and to consolidate its position as a leading tool manufacturer."